Cutting of paragliders is traditionally done with a cold knife, which can be static, rotary or a reciprocating.

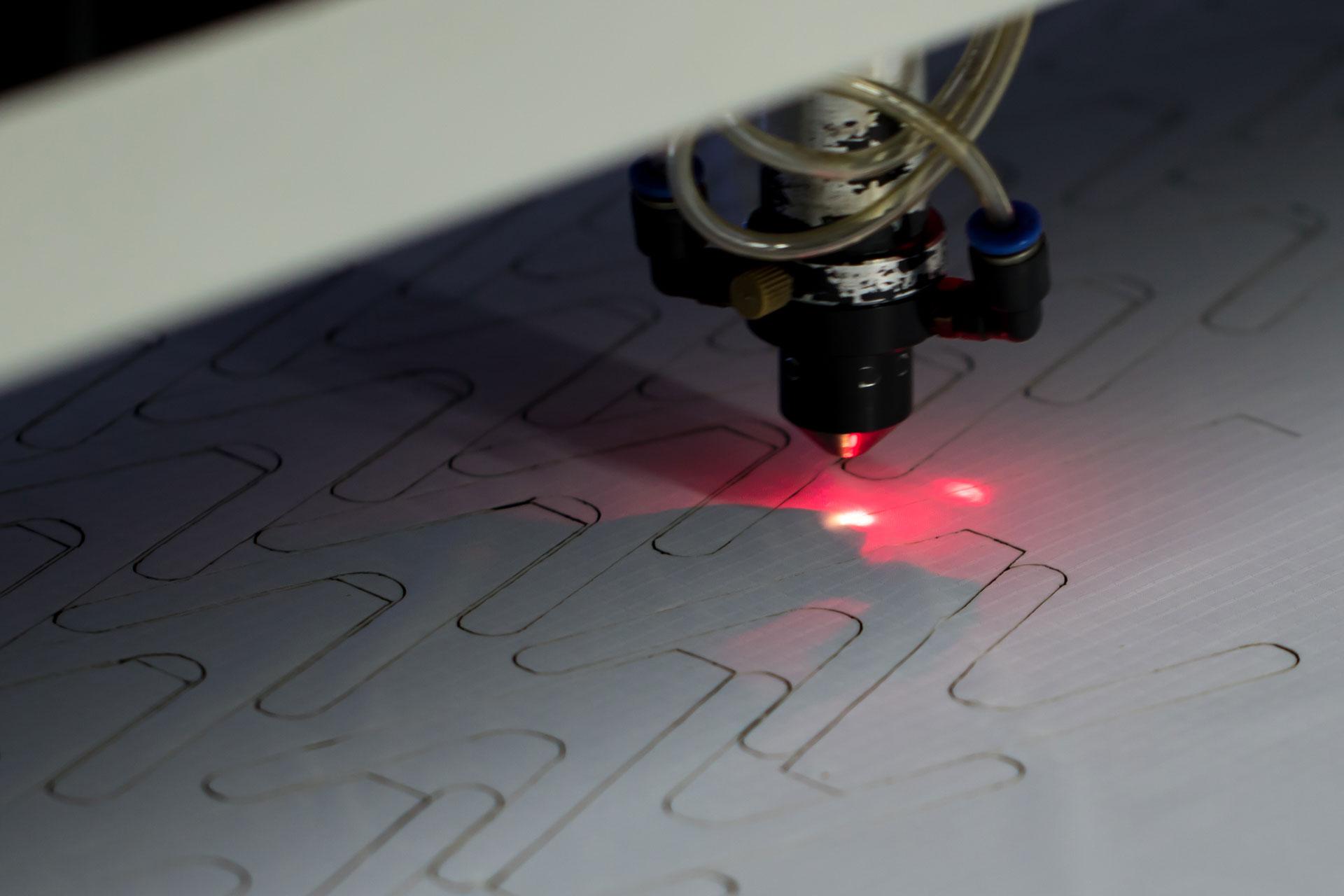

Laser cutting is referred to as “hot cutting”, where the laser-beam cuts (melts) a very thin line in the fabric while moving according to the CAD file containing panels neatly nested to fit the fabric.

Apco’s production facility is equipped with state of the art custom Laser Cutting Machine 10[m] long and 2[m] wide.

This machine operates 24/7 to cut the bulk quantity of gliders produced in our facility.

This machine operates 24/7 to cut the bulk quantity of gliders produced in our facility.

Laser cutting gives many advantages, which ultimately leads to higher performance, better durability and a lighter wing.