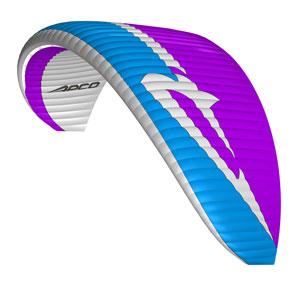

APCO is traditionally known for using materials and building techniques which offer double and triple lifespan over the expected. The glider is made from tear resistant Ripstop Nylon cloth, which is P.U. coated to zero porosity and then siliconized to give the fabric high resistance to the elements. Different cloth is used for the top, bottom and ribs due to their different functions.

As on all APCO wings, the F5 wing uses the same long lasting cloth on the top surface, guaranteeing its integrity for entire expanded lifespan of the wing. Nevertheless we significantly reduced the weight of the wing thanks to advanced solutions applied, without compromising on any of APCO’s legendary durability.

The top surface utilizes our double siliconized cloth – top front is critical area in terms of porosity as this is where most of the lift is generated.

The bottom surface has been upgraded to a lightweight 27 gr. material with an advanced ripstop arrangement which saves additional weight.

The ribs are separated into supported and unsupported ribs, with lightweight material on unsupported ribs for additional weight saving.

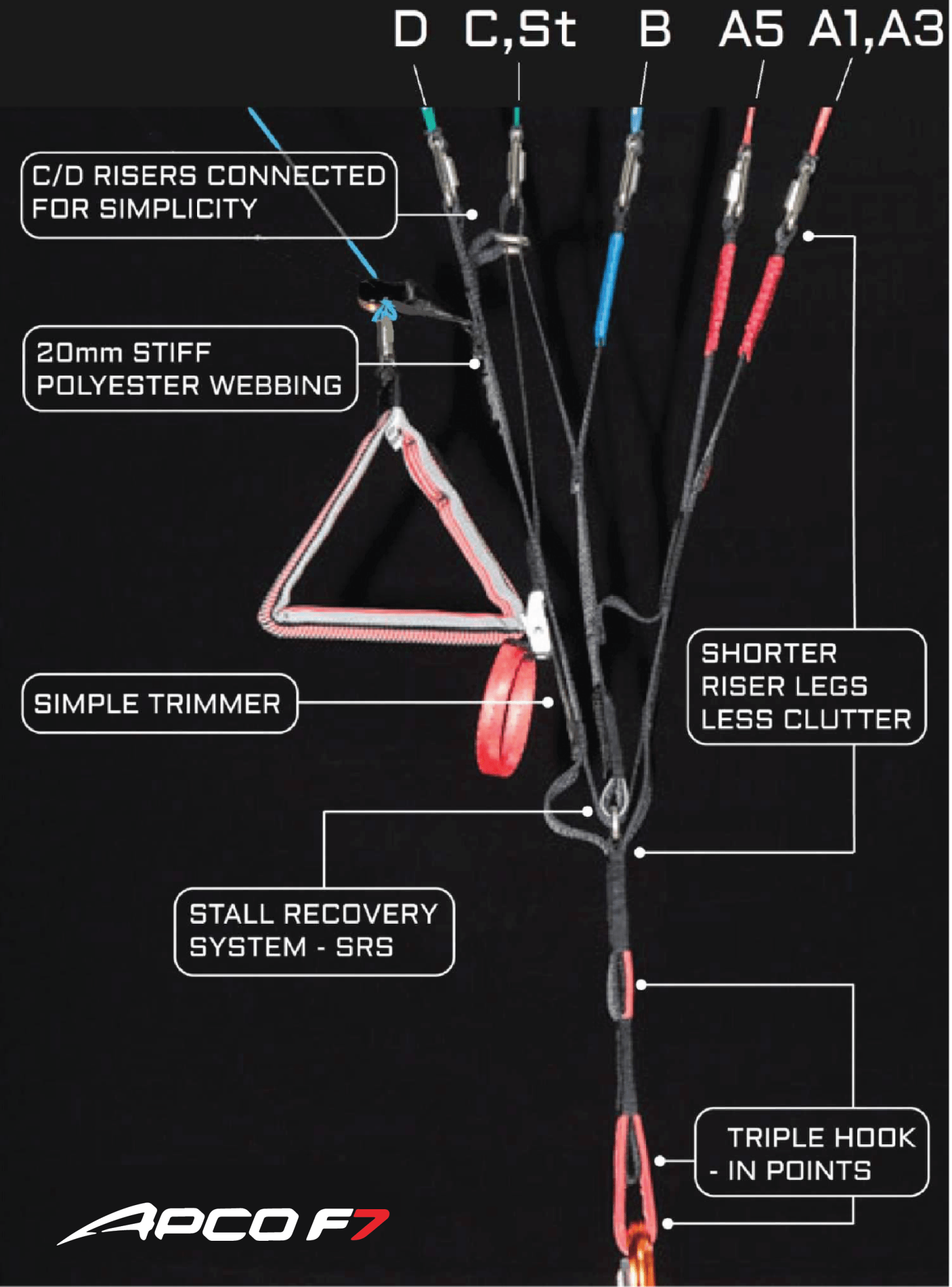

The lines are a mix of different materials in different positions, to optimize to the fullest the diameter/strength according to the required load.

The top lines are our life-time warranted embedded hook in points made from Dyneema fiber.

The rest of the lines are sheathed for extra durability and ease of use. Material used is Kevlar for its stability and resistance to elastic changes in length.

The bottom section of the brake lines is made of Dyneema because of its better mechanical properties. The lines are attached to the risers using Apco’s proprietary aluminum V-links.